- Home Page

- Company Profile

-

Our Products

- Instrumentation Fittings

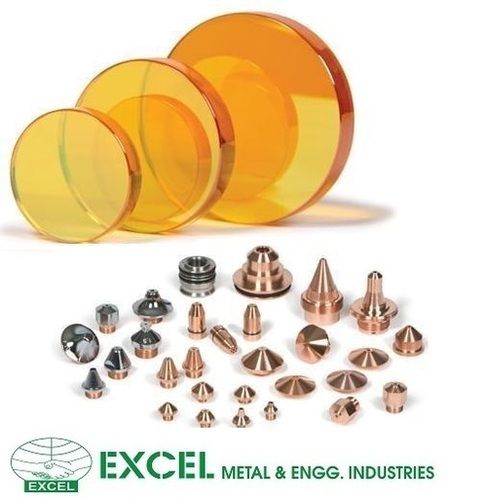

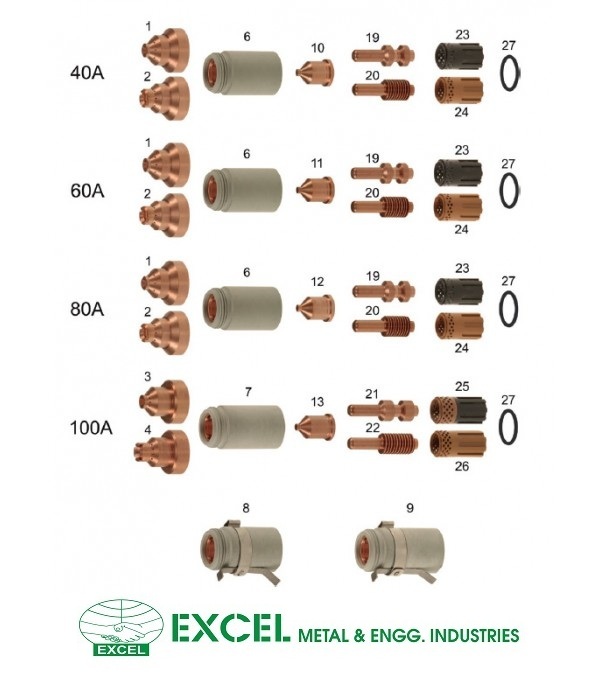

- Plasma Consumables

- Industrial Plasma Torch Consumables

- Hypertherm Plasma Spares

- Plasma torch consumables

- Plasma Cutter Consumables

- Trumpf Laser Consumables

- Ajan Plasma Consumables

- Laser Consumables

- Plasma Consumables

- Hypertherm Nozzle

- Thermal Dynamics Plasma Consumables

- Air Plasma Consumable

- Plasma Spare Parts

- Plasma Consumables Parts

- Hypertherm Coolant

- Plasma Spare Parts

- Industrial Fasteners

- Hex Bolts

- Self Locking Nuts

- U Bolt

- Wedge Anchor

- PTFE Coated Bolts

- SS Fastener

- Stainless steel Hex Bolts

- Stud Bolts

- steel Washer

- Steel U Bolt

- Anchor Bolts

- Studded Tubes

- Aluminum Bronze Fasteners / Aluminum Bronze Bolt Nut Studs

- High Tensile Bolt

- Nickel Alloy Fastener

- Silicon Bronze Fasteners Silicon Bronze Bolts Nuts

- Stainless Steel Fasteners

- Hot Dip Galvanized Bolt

- Threaded Bar

- Titanium Fasteners

- MS Washer

- Brass Fasteners

- Duplex Steel Fastener

- Hastelloy Fasteners

- Galvanized Iron Washer

- Monel Fasteners

- L Bolt

- Shear Connector Stud

- Steel Shear Stud

- Arc Weld Stud

- Eye Bolts

- Industrial Pipe

- DIN 2391 ST52 Carbon Steel Pipe

- Industrial Square Hollow Section Pipe

- Mild Steel Round Pipe

- Stainless Steel 316 Pipe

- Stainless Steel Square Pipe

- Epoxy Coating Round Pipe

- Duplex Steel Round Pipe

- A 106 / API 5L / A53 Gr.B Pipes

- Super Duplex Steel Pipe

- Square Hollow Section Pipe

- Stainless Steel Polished Pipes

- Thick Walled Stainless Steel Pipe

- Slotted Pipes

- Stainless Steel Mirror Pipe

- Mild Steel ERW Pipes

- Steel ERW Pipes

- ms ERW Pipes

- MS jindal ERW Pipes

- MS jindal black ERW Pipes

- MS ERW Pipes

- IS 1239 Black ERW Pipe And Tube

- IS 1239 3589 Pipes

- API Pipes

- Stainless Steel Pipes

- Stainless Steel Tube Coil

- Stainless Steel Slot Pipe

- Alloyed Steel Round Bar

- Pipe Fittings

- Carbon Steel Pipe Elbow

- Inconel Buttweld Reducer

- Stainless Steel Hex Bush

- Stainless Steel Pipe Plugs

- Stainless Steel Stub End

- Copper Pipe Tee

- SS 316 Pipe Tee

- Inconel Buttweld Fittings

- Stainless Steel Fittings

- Alloy 20 Pipe Fittings

- Monel Pipe Fittings

- Titanium Pipe Fittings

- Stainless Steel 310 Pipe Fittings

- Cupro Nickel Pipe Fittings

- Dairy Fittings

- Copper Pipe Fittings

- SS Pipe Fittings

- PIPE FITTINGS

- Seamless Fittings

- WPHY Fittings

- Buttweld fittings

- Barred tee

- Elbow pipe fitting

- Pipe Fitting Elbow

- 904L Fittings

- Duplex Stainless Steel Pipe FItting

- SS 304 Buttweld Fitting

- Duplex Steel Pipe Fittings

- SS 310 Buttweld Fitting

- MS Pipe Fitting

- Alloy Steel Pipe Fittings

- SS 321 Buttweld Fitting

- Alloy 20 Fittings

- WPL6 WPL1 WPL3 Fitting

- Hastelloy Pipe Fitting

- Hastelloy Fitting

- Inconel Fitting

- Carbon Steel Pipe Fittings

- CS Pipe Fittings

- Galvanized Fittings

- Welded Fittings

- Monel Fittings

- SMS Union

- Hammer Union

- MS Pipe Fitting

- Air Header

- Stainless Steel Pipe fittings

- 904 Stainless Steel Stub End

- Steel Tube

- Fabricated Pipes (SS/MS/alloy Steel/ETC)

- API 5L GR X52 / X56 / X60 / X65 / X70 Pipe

- Corten Steel Tube

- Alloy Steel Tube

- Mild Steel Seamless Pipe

- 304 Stainless Steel Pipe

- Epoxy Coating Pipes

- Thick Wall Seamless Pipe

- Stainless Steel Welded Pipe

- Alloy Steel Pipes

- Astm A 179 Seamless Steel Tube

- Seamless Pipe

- Square Pipes

- Stainless Steel 316 Pipes

- Duplex Steel Pipes

- Spiral Welded Pipes

- Carbon Steel Pipes

- Alloy 20 Pipes

- Seamless Stainless Steel Pipe

- ERW Pipe

- Large Diameter Pipes

- Industrial Flanges

- Groove and Tongue Flanges

- 904l Stainless Steel Flanges

- ASTM A182 Blind Flanges

- Brass Flanges

- ASTM A105 Screwed Flanges

- ASTM A351 Blind Flanges

- Stainless Steel Puddle Flange

- Spades Ring Spacers Flanges

- Screwed Flanges

- SORF Flanges

- Customized Flange

- Welding Neck Flanges

- Stainless Steel 304 Flange

- Long Weld Neck Flanges

- Pipe Flanges

- Orifice Flange

- WNRF Flanges

- RTJ Flanges

- Puddle Flanges

- Orifice Plates

- Tube Sheet

- Socket Weld Flanges

- Plate Flanges

- Loose Flanges

- Lapped Joint Flanges

- Reducing Flanges

- BLRF Flanges

- Blind Flanges

- Spectacle Blind Flange

- Hydraulic Pipe Clamp

- Forged Pipe Fittings

- Stainless Steel Sheet

- Industrial Valves

- Tube Fittings

- Single Ferrule Hydraulic Fittings

- 37 Degree Flare Fittings

- Instrumentation Tube

- Adapter Fittings

- Ferrule Tube Fittings

- Double Ferrule Fittings

- Stainless Steel Tube Fittings

- Stainless Steel Hydraulic Fitting

- Precious Pipe Fitting

- Festo Push Fitting

- Din 2353 Hydraulic Tube Fittings

- Hydraulic Bite Type Fittings

- Hydraulic Ferrule Fittings

- Ermeto Tube Fittings

- O-Ring Face Fittings

- Marine Tube Fitting

- Nuts and Ferrule Fittings

- Bulkhead Tube Fitting

- Swagelok Fittings

- Pneumatic Fittings

- SS Adapter Fittings

- Female Connectors

- SS Cross Fittings

- Stainless Steel Camlock Coupling

- Hydraulic Quick Release Coupling

- Quick Release Couplings

- Marine Tube Fitting

- Ms Hydraulic Fittings

- Cs Hydraulic Fittings

- Weld Nipple Fittings

- Voss Equivalent Fittings

- Weld Adapter With Weld Nipple

- 400 Bar Hydraulic Tube Fittings

- 200 Bar Hydraulic Tube Fittings

- DK-LOK Equivalent Fittings

- Industrial Gaskets

- RUBBER GASKET

- Caf Gasket / Cnaf Gasket

- Spiral Wound Gaskets

- Pipe Flanges Gaskets

- API Gasket

- Octagonal Ring Gasket

- Soft Iron Ring Joint Gasket

- Spiral Wound Gasket

- Metal Gasket

- Oval Ring Joint Gasket

- Stainless Steel Ring Joint Gasket

- RTJ Gaskets

- Rubber O Ring

- Dowty Seal

- Graphite Gasket

- Ring Joint Gaskets

- Round Bar

- Alloy 20 Round Bar

- Cast Iron Round Bar

- EN Round Bar

- Inconel Round Bar

- Nitronic 50 Round Bar

- Stainless Steel Bright Bar

- Stainless Steel Round Bar

- Super Duplex Round Bar

- Super Duplex Steel Round Bar

- Tungsten Round Bar

- 17-4 PH Stainless Steel Round Bar

- Stainless Steel 304 Round Bar

- Stainless Steel 321 Round Bar

- Stainless Steel 304 Bright Bar

- Stainless Steel 304L Round Bar

- Stainless Steel 316 Round Bar

- 410 Stainless Steel Round Bar

- Stainless Steel Round Bars 904L

- Stainless Steel Rods

- 309 Stainless Steel Round Bar

- Alloy Round Bar

- Grey Cast Iron Round Bar

- Round Bars

- Aluminium Products

- Aluminium Tubes

- Aluminium Pipes

- Aluminum Coils

- Insulation Aluminum Coil

- IPS Aluminium Tubes / Aluminium IPS Pipe / Aluminium IPS Tubes

- Aluminium Industrial Pipes

- Aluminum sheets

- Aluminium Chequered Plates / Aluminum Checkered Sheet / Aluminum Checkered Plate

- Aluminium Round Bar

- Aluminium Bronze Rod

- Aluminium Angle

- Aluminum Alloy Sheets / Aluminum Sheets / Aluminium Sheets

- Aluminum Bronze Plate

- Aluminum Wires

- IPS Aluminium Tubes Aluminium IPS Pipe Aluminium IPS Tubes

- Compression Fittings

- Pneumatic Products

- Needle Valves

- Hose And Assemblies

- Plasma Cutting Machine

- Weld Stud

- Manifold Valves

- Hastelloy Manifold Valve

- SS Manifold Valves

- Duplex Steel Manifold Valves

- Stainless Steel 316 Manifold Valves

- 2 Way Manifold Valves

- Manifold Valves

- 3 Way Manifold Valves

- 5 Way Manifold Valve

- Block And Bleed Gauge Valves

- SAE 6162 Flanges

- Super Duplex Steel S32750 / S32760 Manifold Valves

- Incoloy 825 Manifold Valves

- Inconel 625 Manifold Valves

- Stainless Steel 304 Manifold Valves

- Inconel Manifold Valve

- Monel Manifold Valves

- Ss 316 Manifold Valve

- Ss 304 Manifold Valve

- Five Valve Manifold, Direct Mount T Type

- Five Valve Manifold Remote Mount

- Hastelloy C276 Manifold Valves

- Ptfe Manifold Valve

- Stainless Steel Manifold Valves

- Carbon Steel Manifold Valves

- Monel Sheet

- Copper Coils

- Hydraulic SAE Flanges

- Structural Steel Products

- Ball Valves

- Bronze Products

- Hastelloy Products

- Refractory Anchors

- Brass Products

- Pressure Gauges

- ERW Pipes

- Microwave Wave Guides

- Brass Tube Fittings

- Titanium Products

- Base Plate

- Condensate Pot

- Metal Pipes

- Polymer Rods

- Stainless Steel Tube Coil

- Expansion Bellow

- Nickel Alloy Products

- Flange Guards

- Dish End Cap

- Welding Consumables

- Stainless Steel Shims

- Cupro Nickel Rods

- Lead Balls

- Nickel Wire

- Half Pipe Sleeve

- Beryllium Copper Wire

- Boiler Steel Plates

- Eye Bolts

- Perforated Sheets

- Metal Powder

- Stainless Steel Sheets

- Stainless Steel 310 Sheets

- Stainless Steel Foil

- Stainless Steel 304 Sheet

- Stainless Steel 309 Sheet

- SS 904L Plate

- Stainless Steel Plate

- Stainless Steel Chequered Plates

- 304 Stainless Steel Plate

- 316 Stainless Steel Plate

- 316L Stainless Steel Plate

- Stainless Steel 321 Plate

- Stainless Steel 310 Plates

- SS 316 Coil

- SS 304 Coil

- Cold Rolled Steel Sheets 304 / 316 / 309 /904 / 310 / 410

- Industrial Thermowell

- Tantalum Products

- Molybdenum Products

- Niobium Products

- Aerospace Fasteners

- Pipe Fittings As Per Type

- Pipe Nipple

- Return Bends

- Lined Fitting ( PTFE Lined / PP Lined / HDPE Lined /Etc)

- Stainless Steel Tee

- Epoxy Coating Pipe Fitting

- Stainless Steel Investment Casting Pipe Fittings

- Buttweld Pipe Fittings

- Stainless steel Bushing

- Pipe Plugs

- Union Fitting

- Pipe Adapters

- Lateral Tee

- 3D Bend

- Hose Nipples

- Pipe Bend

- Pipe Elbow

- Stainless Steel Elbow

- Long Radius Bend

- Stainless Steel Couplings

- Heat Exchanger Tube Plug

- 5D Bend

- Hex Nipple

- Steel Rings

- Hose & Hose Assemblies

- Pipe Clamps

- Flanges as per Material Grade

- Flange as per Standard

- Industrial valves

- Butterfly Valves

- Industrial Valves

- Valve Key

- Knife Gate Valves

- Gate Valves

- Globe Valves

- NRV Valves

- Plug Valve

- Instrumentation Check Valves

- Flanged Valve

- Lined Valves

- Flanged Ball Valve

- High Pressure Ball Valve

- Hydraulic Ball Valve

- Investment Casting Ball Valve

- Ball Valves

- Stainless Steel Ball Valve

- SS Needle Valve

- SS OD Needle Valves

- High Pressure Needle Valves

- Double Ferrule Needle Valve

- Swagelok Needle Valves

- Parker Needle Valve

- Plasma products

- Gauge valves

- Copper Products

- Monel products

- Customized Products

- HYDRAULIC PIPE & HYDRAULIC TUBE

- Tungsten Products

- Inconel Products

- Lead Products

- Pipes

- Fittings As per types

- Flanges

- Tubes

- Fasteners

- Forged Fittings

- SS Product

- Stainless Steel Plate & Sheet

- Valves

- 2 Way Hydraulic Ball Valve

- Three Piece Screwed End Ball Valve

- Hastelloy C276 Needle Valve

- Double Compression Needle Valve

- Duplex Steel Instrumentation Ball Valves

- PTFE Needle Valve

- KHB Ball Valve

- Stainless Steel 316 Instrumentation Ball Valves

- Pp Flange Guard

- Hastelloy Needle Valve

- Monel Needle Valve

- Stainless Steel 304 Needle Valve

- Stainless Steel Needle Valve

- Stainless Steel 316 Needle Valve

- Inconel 625 Needle Valve

- Inconel Needle Valve

- Carbon Steel Needle Valve

- Duplex Steel Needle Valve

- SS310 Needle Valve

- OD X THRD Needle Valves

- Needle Valve Ss

- Swagelok parker Needle Valves

- Stainless Steel threaded Needle Valve

- Ss Needle Valve Screwed

- CS Needle Valve

- Stainless Steel 304 Instrumentation Ball Valves

- Inconel Instrumentation Ball Valves

- Monel Instrumentation Ball Valves

- Hastelloy Instrumentation Ball Valves

- Stainless Steel Instrumentation Ball Valves

- Pp Flanged Ball Valve

- SS Flanged Ball Valve

- CS Flanged Ball Valve

- PTFE Ball Valve

- Ss Three Piece Flanged End Ball Valve

- Three Piece Flanged End Ball Valve

- KHB 2 Way Ball Valve

- Hydraulic 2 Way Ball Valve

- Hydraulic High Pressure Ball Valves

- Flanges as per Standard

- Hydraulic Pipe Clamps

- Pipe Support Clamp

- Stainless Steel Round Bar

- Pneumatics

- CNC Cutting Machine

- Duplex & Super Duplex Products

- Industrial Products

- IS 1239 Black ERW Pipe and Tube

- Air Header, Condensation Pot & Syphon TUBE

- Stainless Steel Pipes & Tubes

- Quick Release Coupling

- Polymer

- Metal Coils

- Alloy Steel Products

- Copper Nickel Products

- Industrial Materials

- Round Bars

- Aerospace Products

- Wires

- Mild Steel Products

- Sheet Plates Coils

- Oil Field Equipment

- Thermowell

- Contact Us

Hypertherm Electrode

200 INR/Kilograms

Product Details:

- Type Plasma Torch Electrode

- Material Copper Alloy

- Capacity 1000 Cuts/Hour

- Computerized No

- Automatic Grade Manual

- Control System Compatible with Hypertherm Powermax Series

- Cutting Speed Varies by system, up to 500 mm/min

- Click to view more

X

Hypertherm Electrode Price And Quantity

- 1 Kilograms

- 200 INR/Kilograms

- Up to 1200°C

- Extended Electrode Life (when used as per manufacturer's guidance)

- Hypertherm Powermax 45/65/85/105

- Blister Pack / Box

- Consumable Part for Plasma Cutting Machines

- 220842 (Example, may vary per variant)

- Polished

Hypertherm Electrode Product Specifications

- Up to 25 mm (depends on system)

- Copper

- 1000 Cuts/Hour

- Copper Alloy

- No

- Direct

- Plasma Cutting

- Manual

- Plasma Torch Electrode

- Varies by system, up to 500 mm/min

- Air Cooled

- 65mm x 20mm x 20mm Approx.

- Compatible with Hypertherm Powermax Series

- 30 Gram Approx.

- Up to 1200°C

- Extended Electrode Life (when used as per manufacturer's guidance)

- Hypertherm Powermax 45/65/85/105

- Blister Pack / Box

- Consumable Part for Plasma Cutting Machines

- 220842 (Example, may vary per variant)

- Polished

Product Description

Buy the formidable Hypertherm Electrode, engineered for glorious performance in plasma cutting applications. This breathtaking copper alloy electrode fits seamlessly with Hypertherm Powermax 45/65/85/105 models, ensuring exceptional compatibility and reliable process control. Find superior consumable quality with a polished finish, extended lifespan, and remarkable capacity-achieving up to 1,000 cuts per hour at operating temperatures up to 1200C. Secure a discount or bulk offer from our trusted suppliers, traders, and wholesalers across India. Each unit comes securely delivered in blister pack or box, with part number 220842 (variants available), ready for use with air-cooled plasma torches.

Expert Application of Hypertherm Electrode

The Hypertherm Electrode is expertly crafted for manual plasma cutting machines, making it the ideal consumable part for industrial workshops, fabrication units, and onsite maintenance. Compatible with Powermax models, it performs on various metal surfaces-ranging from mild steel to stainless. Its polished surface ensures minimal resistance and optimal conductivity, delivering precise cuts on workpieces up to 25 mm thick. Choose this electrode for efficient and clean application across diverse workspace environments.

Effortless Supply & Transaction Process

With our robust supply ability, you can quickly handover orders for Hypertherm Electrodes to ensure timely project shipment. Payment terms are flexible, designed for seamless exchange, allowing buyers to transact with ease. We offer sample units upon request to validate quality before bulk procurement. Our streamlined dispatch and reliable logistic partnerships guarantee prompt delivery and hassle-free replacement, empowering your operations with trusted consumable support.

Expert Application of Hypertherm Electrode

The Hypertherm Electrode is expertly crafted for manual plasma cutting machines, making it the ideal consumable part for industrial workshops, fabrication units, and onsite maintenance. Compatible with Powermax models, it performs on various metal surfaces-ranging from mild steel to stainless. Its polished surface ensures minimal resistance and optimal conductivity, delivering precise cuts on workpieces up to 25 mm thick. Choose this electrode for efficient and clean application across diverse workspace environments.

Effortless Supply & Transaction Process

With our robust supply ability, you can quickly handover orders for Hypertherm Electrodes to ensure timely project shipment. Payment terms are flexible, designed for seamless exchange, allowing buyers to transact with ease. We offer sample units upon request to validate quality before bulk procurement. Our streamlined dispatch and reliable logistic partnerships guarantee prompt delivery and hassle-free replacement, empowering your operations with trusted consumable support.

FAQ's of Hypertherm Electrode:

Q: How is the Hypertherm Electrode used in plasma cutting processes?

A: The Hypertherm Electrode is installed in compatible Powermax plasma torches and functions as a crucial consumable, enabling precise metal cutting by conducting high-energy plasma arcs onto the desired work surface.Q: What models are compatible with this electrode?

A: This electrode is compatible with Hypertherm Powermax 45, 65, 85, and 105 plasma cutting systems, ensuring broad usability across multiple platforms.Q: Where can I purchase the Hypertherm Electrode with a discount?

A: You can find these electrodes for sale from manufacturers, suppliers, traders, and wholesalers throughout India. Discounts or bulk pricing are often available, depending on order quantity and supplier terms.Q: When should the electrode be replaced for optimal cutting performance?

A: Replace the electrode when you notice diminished cutting quality, increased resistance, or after reaching its rated lifespan-always following the manufacturer's maintenance guidance for the best results.Q: What is the process for ordering and receiving sample electrodes?

A: You may request sample units through the supplier or manufacturer prior to a bulk handover. Upon confirmation, shipment of samples is arranged for testing and quality verification.Q: How does extended electrode life benefit my operation?

A: An extended electrode lifespan reduces downtime and replacement costs, enhancing process efficiency and allowing for sustained high-cutting capacity during demanding fabrication jobs.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email