- Home Page

- Company Profile

-

Our Products

- Instrumentation Fittings

- Plasma Consumables

- Industrial Plasma Torch Consumables

- Hypertherm Plasma Spares

- Plasma torch consumables

- Plasma Cutter Consumables

- Trumpf Laser Consumables

- Ajan Plasma Consumables

- Laser Consumables

- Plasma Consumables

- Hypertherm Nozzle

- Thermal Dynamics Plasma Consumables

- Air Plasma Consumable

- Plasma Spare Parts

- Plasma Consumables Parts

- Hypertherm Coolant

- Plasma Spare Parts

- Industrial Fasteners

- Hex Bolts

- Self Locking Nuts

- U Bolt

- Wedge Anchor

- PTFE Coated Bolts

- SS Fastener

- Stainless steel Hex Bolts

- Stud Bolts

- steel Washer

- Steel U Bolt

- Anchor Bolts

- Studded Tubes

- Aluminum Bronze Fasteners / Aluminum Bronze Bolt Nut Studs

- High Tensile Bolt

- Nickel Alloy Fastener

- Silicon Bronze Fasteners Silicon Bronze Bolts Nuts

- Stainless Steel Fasteners

- Hot Dip Galvanized Bolt

- Threaded Bar

- Titanium Fasteners

- MS Washer

- Brass Fasteners

- Duplex Steel Fastener

- Hastelloy Fasteners

- Galvanized Iron Washer

- Monel Fasteners

- L Bolt

- Shear Connector Stud

- Steel Shear Stud

- Arc Weld Stud

- Eye Bolts

- Industrial Pipe

- DIN 2391 ST52 Carbon Steel Pipe

- Industrial Square Hollow Section Pipe

- Mild Steel Round Pipe

- Stainless Steel 316 Pipe

- Stainless Steel Square Pipe

- Epoxy Coating Round Pipe

- Duplex Steel Round Pipe

- A 106 / API 5L / A53 Gr.B Pipes

- Super Duplex Steel Pipe

- Square Hollow Section Pipe

- Stainless Steel Polished Pipes

- Thick Walled Stainless Steel Pipe

- Slotted Pipes

- Stainless Steel Mirror Pipe

- Mild Steel ERW Pipes

- Steel ERW Pipes

- ms ERW Pipes

- MS jindal ERW Pipes

- MS jindal black ERW Pipes

- MS ERW Pipes

- IS 1239 Black ERW Pipe And Tube

- IS 1239 3589 Pipes

- API Pipes

- Stainless Steel Pipes

- Stainless Steel Tube Coil

- Stainless Steel Slot Pipe

- Alloyed Steel Round Bar

- Pipe Fittings

- Carbon Steel Pipe Elbow

- Inconel Buttweld Reducer

- Stainless Steel Hex Bush

- Stainless Steel Pipe Plugs

- Stainless Steel Stub End

- Copper Pipe Tee

- SS 316 Pipe Tee

- Inconel Buttweld Fittings

- Alloy 20 Pipe Fittings

- Stainless Steel Fittings

- Monel Pipe Fittings

- Titanium Pipe Fittings

- Stainless Steel 310 Pipe Fittings

- Dairy Fittings

- Cupro Nickel Pipe Fittings

- Copper Pipe Fittings

- SS Pipe Fittings

- PIPE FITTINGS

- Seamless Fittings

- WPHY Fittings

- Buttweld fittings

- Barred tee

- Elbow pipe fitting

- Pipe Fitting Elbow

- 904L Fittings

- Duplex Stainless Steel Pipe FItting

- SS 304 Buttweld Fitting

- Duplex Steel Pipe Fittings

- SS 310 Buttweld Fitting

- MS Pipe Fitting

- Alloy Steel Pipe Fittings

- SS 321 Buttweld Fitting

- Alloy 20 Fittings

- WPL6 WPL1 WPL3 Fitting

- Hastelloy Pipe Fitting

- Hastelloy Fitting

- Inconel Fitting

- Carbon Steel Pipe Fittings

- CS Pipe Fittings

- Galvanized Fittings

- Welded Fittings

- Monel Fittings

- SMS Union

- Hammer Union

- MS Pipe Fitting

- Air Header

- Stainless Steel Pipe fittings

- 904 Stainless Steel Stub End

- Steel Tube

- Fabricated Pipes (SS/MS/alloy Steel/ETC)

- API 5L GR X52 / X56 / X60 / X65 / X70 Pipe

- Corten Steel Tube

- Alloy Steel Tube

- Mild Steel Seamless Pipe

- 304 Stainless Steel Pipe

- Epoxy Coating Pipes

- Thick Wall Seamless Pipe

- Stainless Steel Welded Pipe

- Alloy Steel Pipes

- Astm A 179 Seamless Steel Tube

- Seamless Pipe

- Square Pipes

- Stainless Steel 316 Pipes

- Duplex Steel Pipes

- Spiral Welded Pipes

- Carbon Steel Pipes

- Alloy 20 Pipes

- Seamless Stainless Steel Pipe

- ERW Pipe

- Large Diameter Pipes

- Industrial Flanges

- Groove and Tongue Flanges

- 904l Stainless Steel Flanges

- ASTM A182 Blind Flanges

- Brass Flanges

- ASTM A105 Screwed Flanges

- ASTM A351 Blind Flanges

- Stainless Steel Puddle Flange

- Spades Ring Spacers Flanges

- Screwed Flanges

- SORF Flanges

- Customized Flange

- Welding Neck Flanges

- Stainless Steel 304 Flange

- Long Weld Neck Flanges

- Pipe Flanges

- Orifice Flange

- WNRF Flanges

- RTJ Flanges

- Puddle Flanges

- Orifice Plates

- Tube Sheet

- Socket Weld Flanges

- Plate Flanges

- Loose Flanges

- Lapped Joint Flanges

- Reducing Flanges

- BLRF Flanges

- Blind Flanges

- Spectacle Blind Flange

- Hydraulic Pipe Clamp

- Forged Pipe Fittings

- Stainless Steel Sheet

- Industrial Valves

- Tube Fittings

- Single Ferrule Hydraulic Fittings

- 37 Degree Flare Fittings

- Instrumentation Tube

- Adapter Fittings

- Ferrule Tube Fittings

- Double Ferrule Fittings

- Stainless Steel Tube Fittings

- Stainless Steel Hydraulic Fitting

- Precious Pipe Fitting

- Festo Push Fitting

- Din 2353 Hydraulic Tube Fittings

- Hydraulic Bite Type Fittings

- Hydraulic Ferrule Fittings

- Ermeto Tube Fittings

- O-Ring Face Fittings

- Marine Tube Fitting

- Nuts and Ferrule Fittings

- Bulkhead Tube Fitting

- Swagelok Fittings

- Pneumatic Fittings

- SS Adapter Fittings

- Female Connectors

- SS Cross Fittings

- Stainless Steel Camlock Coupling

- Hydraulic Quick Release Coupling

- Quick Release Couplings

- Marine Tube Fitting

- Ms Hydraulic Fittings

- Cs Hydraulic Fittings

- Weld Nipple Fittings

- Voss Equivalent Fittings

- Weld Adapter With Weld Nipple

- 400 Bar Hydraulic Tube Fittings

- 200 Bar Hydraulic Tube Fittings

- DK-LOK Equivalent Fittings

- Industrial Gaskets

- RUBBER GASKET

- Caf Gasket / Cnaf Gasket

- Spiral Wound Gaskets

- Pipe Flanges Gaskets

- API Gasket

- Octagonal Ring Gasket

- Soft Iron Ring Joint Gasket

- Spiral Wound Gasket

- Metal Gasket

- Oval Ring Joint Gasket

- Stainless Steel Ring Joint Gasket

- RTJ Gaskets

- Rubber O Ring

- Dowty Seal

- Graphite Gasket

- Ring Joint Gaskets

- Round Bar

- Alloy 20 Round Bar

- Cast Iron Round Bar

- EN Round Bar

- Inconel Round Bar

- Nitronic 50 Round Bar

- Stainless Steel Bright Bar

- Stainless Steel Round Bar

- Super Duplex Round Bar

- Super Duplex Steel Round Bar

- Tungsten Round Bar

- 17-4 PH Stainless Steel Round Bar

- Stainless Steel 304 Round Bar

- Stainless Steel 321 Round Bar

- Stainless Steel 304 Bright Bar

- Stainless Steel 304L Round Bar

- Stainless Steel 316 Round Bar

- 410 Stainless Steel Round Bar

- Stainless Steel Round Bars 904L

- Stainless Steel Rods

- 309 Stainless Steel Round Bar

- Alloy Round Bar

- Grey Cast Iron Round Bar

- Round Bars

- Aluminium Products

- Aluminium Tubes

- Aluminium Pipes

- Aluminum Coils

- Insulation Aluminum Coil

- IPS Aluminium Tubes / Aluminium IPS Pipe / Aluminium IPS Tubes

- Aluminium Industrial Pipes

- Aluminum sheets

- Aluminium Chequered Plates / Aluminum Checkered Sheet / Aluminum Checkered Plate

- Aluminium Round Bar

- Aluminium Bronze Rod

- Aluminium Angle

- Aluminum Alloy Sheets / Aluminum Sheets / Aluminium Sheets

- Aluminum Bronze Plate

- Aluminum Wires

- IPS Aluminium Tubes Aluminium IPS Pipe Aluminium IPS Tubes

- Compression Fittings

- Pneumatic Products

- Needle Valves

- Hose And Assemblies

- Plasma Cutting Machine

- Weld Stud

- Manifold Valves

- Duplex Steel Manifold Valves

- Hastelloy Manifold Valve

- SS Manifold Valves

- Stainless Steel 316 Manifold Valves

- 2 Way Manifold Valves

- Manifold Valves

- 3 Way Manifold Valves

- 5 Way Manifold Valve

- Block And Bleed Gauge Valves

- SAE 6162 Flanges

- Super Duplex Steel S32750 / S32760 Manifold Valves

- Incoloy 825 Manifold Valves

- Inconel 625 Manifold Valves

- Stainless Steel 304 Manifold Valves

- Inconel Manifold Valve

- Monel Manifold Valves

- Ss 316 Manifold Valve

- Ss 304 Manifold Valve

- Five Valve Manifold, Direct Mount T Type

- Five Valve Manifold Remote Mount

- Hastelloy C276 Manifold Valves

- Ptfe Manifold Valve

- Stainless Steel Manifold Valves

- Carbon Steel Manifold Valves

- Monel Sheet

- Copper Coils

- Hydraulic SAE Flanges

- Structural Steel Products

- Ball Valves

- Bronze Products

- Hastelloy Products

- Refractory Anchors

- Brass Products

- Pressure Gauges

- ERW Pipes

- Microwave Wave Guides

- Brass Tube Fittings

- Titanium Products

- Base Plate

- Condensate Pot

- Metal Pipes

- Polymer Rods

- Stainless Steel Tube Coil

- Expansion Bellow

- Nickel Alloy Products

- Flange Guards

- Dish End Cap

- Welding Consumables

- Stainless Steel Shims

- Cupro Nickel Rods

- Lead Balls

- Nickel Wire

- Half Pipe Sleeve

- Beryllium Copper Wire

- Boiler Steel Plates

- Eye Bolts

- Perforated Sheets

- Metal Powder

- Stainless Steel Sheets

- Stainless Steel 310 Sheets

- Stainless Steel Foil

- Stainless Steel 304 Sheet

- Stainless Steel 309 Sheet

- SS 904L Plate

- Stainless Steel Plate

- Stainless Steel Chequered Plates

- 304 Stainless Steel Plate

- 316 Stainless Steel Plate

- 316L Stainless Steel Plate

- Stainless Steel 321 Plate

- Stainless Steel 310 Plates

- SS 316 Coil

- SS 304 Coil

- Cold Rolled Steel Sheets 304 / 316 / 309 /904 / 310 / 410

- Industrial Thermowell

- Tantalum Products

- Molybdenum Products

- Niobium Products

- Aerospace Fasteners

- Pipe Fittings As Per Type

- Pipe Nipple

- Return Bends

- Lined Fitting ( PTFE Lined / PP Lined / HDPE Lined /Etc)

- Stainless Steel Tee

- Epoxy Coating Pipe Fitting

- Stainless Steel Investment Casting Pipe Fittings

- Buttweld Pipe Fittings

- Stainless steel Bushing

- Pipe Plugs

- Union Fitting

- Pipe Adapters

- Lateral Tee

- 3D Bend

- Hose Nipples

- Pipe Bend

- Pipe Elbow

- Stainless Steel Elbow

- Long Radius Bend

- Stainless Steel Couplings

- Heat Exchanger Tube Plug

- 5D Bend

- Hex Nipple

- Steel Rings

- Hose & Hose Assemblies

- Pipe Clamps

- Flanges as per Material Grade

- Flange as per Standard

- Industrial valves

- Butterfly Valves

- Industrial Valves

- Valve Key

- Knife Gate Valves

- Gate Valves

- Globe Valves

- NRV Valves

- Plug Valve

- Instrumentation Check Valves

- Flanged Valve

- Lined Valves

- Flanged Ball Valve

- High Pressure Ball Valve

- Hydraulic Ball Valve

- Investment Casting Ball Valve

- Ball Valves

- Stainless Steel Ball Valve

- SS Needle Valve

- SS OD Needle Valves

- High Pressure Needle Valves

- Double Ferrule Needle Valve

- Swagelok Needle Valves

- Parker Needle Valve

- Plasma products

- Gauge valves

- Copper Products

- Monel products

- Customized Products

- HYDRAULIC PIPE & HYDRAULIC TUBE

- Tungsten Products

- Inconel Products

- Lead Products

- Pipes

- Fittings As per types

- Flanges

- Tubes

- Fasteners

- Forged Fittings

- SS Product

- Stainless Steel Plate & Sheet

- Valves

- Stainless Steel 316 Instrumentation Ball Valves

- Double Compression Needle Valve

- Duplex Steel Instrumentation Ball Valves

- KHB Ball Valve

- PTFE Needle Valve

- 2 Way Hydraulic Ball Valve

- Three Piece Screwed End Ball Valve

- Hastelloy C276 Needle Valve

- Pp Flange Guard

- Hastelloy Needle Valve

- Monel Needle Valve

- Stainless Steel 304 Needle Valve

- Stainless Steel Needle Valve

- Stainless Steel 316 Needle Valve

- Inconel 625 Needle Valve

- Inconel Needle Valve

- Carbon Steel Needle Valve

- Duplex Steel Needle Valve

- SS310 Needle Valve

- OD X THRD Needle Valves

- Needle Valve Ss

- Swagelok parker Needle Valves

- Stainless Steel threaded Needle Valve

- Ss Needle Valve Screwed

- CS Needle Valve

- Stainless Steel 304 Instrumentation Ball Valves

- Inconel Instrumentation Ball Valves

- Monel Instrumentation Ball Valves

- Hastelloy Instrumentation Ball Valves

- Stainless Steel Instrumentation Ball Valves

- Pp Flanged Ball Valve

- SS Flanged Ball Valve

- CS Flanged Ball Valve

- PTFE Ball Valve

- Ss Three Piece Flanged End Ball Valve

- Three Piece Flanged End Ball Valve

- KHB 2 Way Ball Valve

- Hydraulic 2 Way Ball Valve

- Hydraulic High Pressure Ball Valves

- Flanges as per Standard

- Hydraulic Pipe Clamps

- Pipe Support Clamp

- Stainless Steel Round Bar

- Pneumatics

- CNC Cutting Machine

- Duplex & Super Duplex Products

- Industrial Products

- IS 1239 Black ERW Pipe and Tube

- Air Header, Condensation Pot & Syphon TUBE

- Stainless Steel Pipes & Tubes

- Quick Release Coupling

- Polymer

- Metal Coils

- Alloy Steel Products

- Copper Nickel Products

- Industrial Materials

- Round Bars

- Aerospace Products

- Wires

- Mild Steel Products

- Sheet Plates Coils

- Oil Field Equipment

- Thermowell

- Contact Us

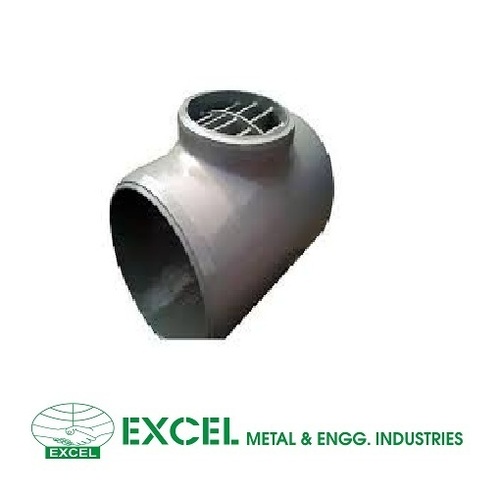

Barred tee

100 INR/Number

Product Details:

- Yield Strength 240 MPa (min) Depending on material

- Tolerance 1% dimensional tolerance

- Tensile Strength 415 MPa (min) Depending on material

- Connection Type Butt Weld

- Flexibility Rigid

- Temperature Range -20C to +600C

- Bend Radius Standard as per ASME specifications

- Click to view more

X

Barred tee Price And Quantity

- 99.00 - 200.00 INR/Number

- 10 Number

- 100 INR/Number

- Plain End, Bevel End

- 100% Visual and Dimensional Inspection

- High for SS, Moderate for CS with coating

- Standard 50 mm or as required

- Wooden Box, Pallet or as requested

- Prevents passage of pipeline pigs or scrapers

- Welded Internal Bars (per project spec)

- Hot/Cold Formed, Seamless or Welded

Barred tee Product Specifications

- 1/2 to 48

- Oil & Gas, Petrochemical, Chemical Industries, Pipeline Systems

- 1/2 to 48 (DN15~DN1200)

- Not Threaded (Butt Weld)

- Anti-corrosive coating (as per customer requirement)

- Sch 10 to Sch 160

- Metal-to-metal

- Pipeline pigging operations, preventing passage of pigs, scraper, or sphere

- Round

- Black-coated, Pickled, Passivated, or Sandblasted

- Standard as per ASME specifications

- Standard and custom lengths available

- Butt Weld

- Rigid

- Class 150 to Class 2500

- -20C to +600C

- Carbon Steel / Stainless Steel / Alloy Steel

- T-shaped with internal bar system

- Barred Tee

- 415 MPa (min) Depending on material

- 1% dimensional tolerance

- 240 MPa (min) Depending on material

- Black or Metallic Grey

- A234 WPB / WP11 / WP22 / WP91 / ASTM A403 WP304, WP316

- ASTM A234 / ASME B16.9 / MSS-SP-75

- Welded

- Plain End, Bevel End

- 100% Visual and Dimensional Inspection

- High for SS, Moderate for CS with coating

- Standard 50 mm or as required

- Wooden Box, Pallet or as requested

- Prevents passage of pipeline pigs or scrapers

- Welded Internal Bars (per project spec)

- Hot/Cold Formed, Seamless or Welded

Product Description

Size : 1/2"NB TO 48"NB IN Schedule: SCH20, SCH30, SCH40, STD, SCH80, XS, SCH60, SCH80, SCH120, SCH140, SCH160, XXS Type : Seamless / ERW / Welded / Fabricated Form : Equal Tee, Reducing Tee, Barred Tee , Lateral Tee. Materials : Stainless Steel Tee SS Tee ASTM A403 WP Gr. 304, 304H, 309, 310, 316, 316L, 317L, 321, 347, 904L Carbon Steel Tee CS Tee ASTM A 234 WPB , WPBW, WPHY 42, WPHY 46, WPHY 52, WPH 60, WPHY 65 & WPHY 70. Low Temperature Carbon Steel Tee LTCS Tee ASTM A420 WPL3 / A420WPL6 Alloy Steel Tee AS Tee ASTM / ASME A/SA 234 Gr. WP 1, WP 5, WP 9, WP 11, WP 12, WP 22, WP 91 Duplex Steel Tee ASTM A 815 UNS NO S 31803 , S 32205. Nickel Alloy Stubend:Engineered for Extreme Pipeline Conditions

Barred tees are specifically manufactured to withstand the rigors of demanding pipeline systems in oil & gas, petrochemical, and chemical industries. Their robust construction and high resistance to corrosion, especially in stainless-steel variants, ensure longevity even under high pressure and temperature conditions.

Precision Manufacturing and Inspection

Adhering to stringent standards such as ASTM A234 and ASME B16.9, every barred tee undergoes 100% visual and dimensional inspection. This rigorous process ensures tight tolerance (1%) and flawless performance in critical applications. Customizable options in length, coating, and material are available to meet specific project needs.

Optimized Functionality for Safe Operations

The integral bar system within each barred tee reliably prevents the passage of pipeline pigs and scrapers, securing equipment within the pipeline. This design maximizes operational safety and efficiency during pipeline pigging operations, while an anti-corrosive coating further enhances product durability.

FAQs of Barred tee:

Q: How does a barred tee prevent the passage of pipeline pigs or scrapers?

A: A barred tee incorporates welded internal bars across the branch opening, forming a physical barrier. This bar system stops pigs, scrapers, or spheres from entering or exiting the branch, ensuring they remain within the intended pipeline section during pigging operations.Q: What materials and standards are used for manufacturing barred tees?

A: Barred tees are crafted from carbon steel, stainless steel, or alloy steel, according to ASTM A234, ASME B16.9, and MSS-SP-75 standards. The material grade is selected based on project requirements, ensuring suitable tensile and yield strength.Q: When should I choose a barred tee with plain or bevel ends?

A: Plain and bevel ends are chosen based on the pipe connection method. Bevel ends provide a prepared surface for butt welding, creating strong and leak-free joints in high-pressure applications. Plain ends are generally used when welding preparation or field customization is necessary.Q: Where are barred tees predominantly used?

A: These tees are employed in oil & gas, petrochemical, chemical, and other industrial pipeline systems where the prevention of pig or scraper passage is essential to operational integrity and safety.Q: What is the manufacturing and inspection process for barred tees?

A: Barred tees are manufactured using hot or cold forming, followed by seamless or welded fabrication as per specifications. Each tee is subjected to 100% visual and dimensional inspection to ensure compliance with quality and tolerance requirements before shipment.Q: How are barred tees packaged and protected during transport?

A: For safe transit and delivery, barred tees are packaged in wooden boxes, pallets, or as per customer requests. Coating options such as black-coating, pickling, or passivation are available to augment corrosion resistance during storage and shipment.Q: What are the main benefits of using barred tees in pipeline systems?

A: Barred tees enhance pipeline safety during pigging by preventing equipment loss or damage, accommodate a wide range of sizes and pressures, and offer reliable corrosion protectioncontributing to reduced maintenance and extended service life in challenging industrial environments.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Call Me Free

Call Me Free