- Home Page

- Company Profile

-

Our Products

- Instrumentation Fittings

- Plasma Consumables

- Industrial Plasma Torch Consumables

- Hypertherm Plasma Spares

- Plasma torch consumables

- Plasma Cutter Consumables

- Trumpf Laser Consumables

- Ajan Plasma Consumables

- Laser Consumables

- Plasma Consumables

- Hypertherm Nozzle

- Thermal Dynamics Plasma Consumables

- Air Plasma Consumable

- Plasma Spare Parts

- Plasma Consumables Parts

- Hypertherm Coolant

- Plasma Spare Parts

- Industrial Fasteners

- Hex Bolts

- Self Locking Nuts

- U Bolt

- Wedge Anchor

- PTFE Coated Bolts

- SS Fastener

- Stainless steel Hex Bolts

- Stud Bolts

- steel Washer

- Steel U Bolt

- Anchor Bolts

- Studded Tubes

- Aluminum Bronze Fasteners / Aluminum Bronze Bolt Nut Studs

- High Tensile Bolt

- Nickel Alloy Fastener

- Silicon Bronze Fasteners Silicon Bronze Bolts Nuts

- Stainless Steel Fasteners

- Hot Dip Galvanized Bolt

- Threaded Bar

- Titanium Fasteners

- MS Washer

- Brass Fasteners

- Duplex Steel Fastener

- Hastelloy Fasteners

- Galvanized Iron Washer

- Monel Fasteners

- L Bolt

- Shear Connector Stud

- Steel Shear Stud

- Arc Weld Stud

- Eye Bolts

- Industrial Pipe

- DIN 2391 ST52 Carbon Steel Pipe

- Industrial Square Hollow Section Pipe

- Mild Steel Round Pipe

- Stainless Steel 316 Pipe

- Stainless Steel Square Pipe

- Epoxy Coating Round Pipe

- Duplex Steel Round Pipe

- A 106 / API 5L / A53 Gr.B Pipes

- Super Duplex Steel Pipe

- Square Hollow Section Pipe

- Stainless Steel Polished Pipes

- Thick Walled Stainless Steel Pipe

- Slotted Pipes

- Stainless Steel Mirror Pipe

- Mild Steel ERW Pipes

- Steel ERW Pipes

- ms ERW Pipes

- MS jindal ERW Pipes

- MS jindal black ERW Pipes

- MS ERW Pipes

- IS 1239 Black ERW Pipe And Tube

- IS 1239 3589 Pipes

- API Pipes

- Stainless Steel Pipes

- Stainless Steel Tube Coil

- Stainless Steel Slot Pipe

- Alloyed Steel Round Bar

- Pipe Fittings

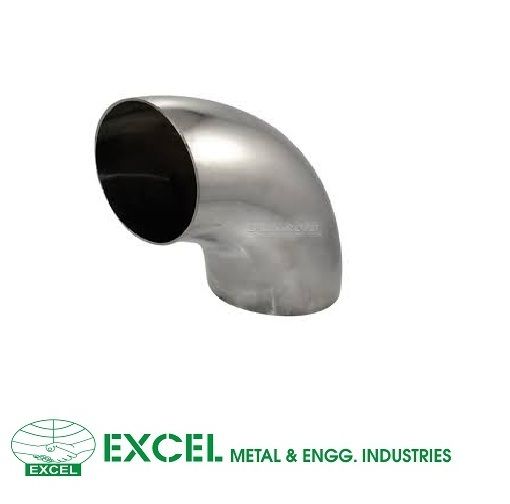

- Carbon Steel Pipe Elbow

- Inconel Buttweld Reducer

- Stainless Steel Hex Bush

- Stainless Steel Pipe Plugs

- Stainless Steel Stub End

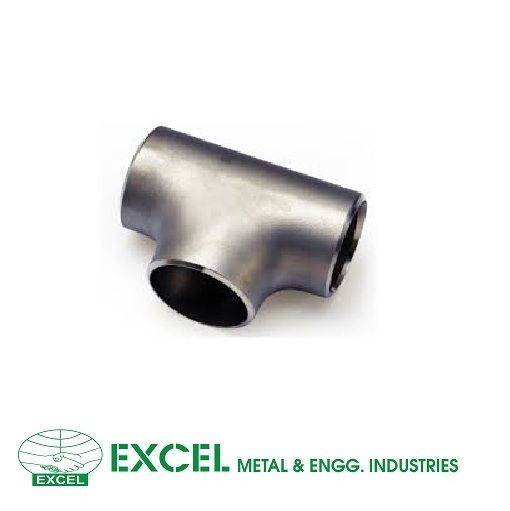

- Copper Pipe Tee

- SS 316 Pipe Tee

- Inconel Buttweld Fittings

- Alloy 20 Pipe Fittings

- Stainless Steel Fittings

- Monel Pipe Fittings

- Titanium Pipe Fittings

- Stainless Steel 310 Pipe Fittings

- Dairy Fittings

- Cupro Nickel Pipe Fittings

- Copper Pipe Fittings

- SS Pipe Fittings

- PIPE FITTINGS

- Seamless Fittings

- WPHY Fittings

- Buttweld fittings

- Barred tee

- Elbow pipe fitting

- Pipe Fitting Elbow

- 904L Fittings

- Duplex Stainless Steel Pipe FItting

- SS 304 Buttweld Fitting

- Duplex Steel Pipe Fittings

- SS 310 Buttweld Fitting

- MS Pipe Fitting

- Alloy Steel Pipe Fittings

- SS 321 Buttweld Fitting

- Alloy 20 Fittings

- WPL6 WPL1 WPL3 Fitting

- Hastelloy Pipe Fitting

- Hastelloy Fitting

- Inconel Fitting

- Carbon Steel Pipe Fittings

- CS Pipe Fittings

- Galvanized Fittings

- Welded Fittings

- Monel Fittings

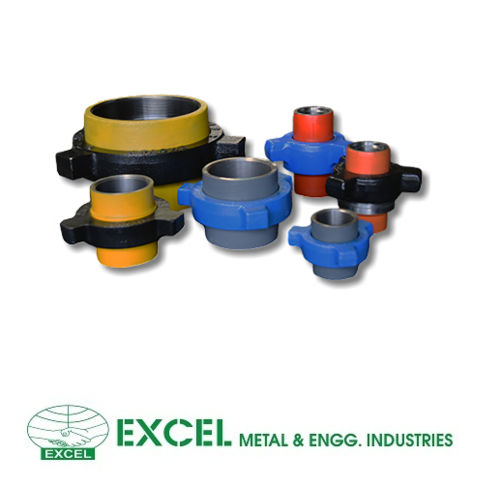

- SMS Union

- Hammer Union

- MS Pipe Fitting

- Air Header

- Stainless Steel Pipe fittings

- 904 Stainless Steel Stub End

- Steel Tube

- Fabricated Pipes (SS/MS/alloy Steel/ETC)

- API 5L GR X52 / X56 / X60 / X65 / X70 Pipe

- Corten Steel Tube

- Alloy Steel Tube

- Mild Steel Seamless Pipe

- 304 Stainless Steel Pipe

- Epoxy Coating Pipes

- Thick Wall Seamless Pipe

- Stainless Steel Welded Pipe

- Alloy Steel Pipes

- Astm A 179 Seamless Steel Tube

- Seamless Pipe

- Square Pipes

- Stainless Steel 316 Pipes

- Duplex Steel Pipes

- Spiral Welded Pipes

- Carbon Steel Pipes

- Alloy 20 Pipes

- Seamless Stainless Steel Pipe

- ERW Pipe

- Large Diameter Pipes

- Industrial Flanges

- Groove and Tongue Flanges

- 904l Stainless Steel Flanges

- ASTM A182 Blind Flanges

- Brass Flanges

- ASTM A105 Screwed Flanges

- ASTM A351 Blind Flanges

- Stainless Steel Puddle Flange

- Spades Ring Spacers Flanges

- Screwed Flanges

- SORF Flanges

- Customized Flange

- Welding Neck Flanges

- Stainless Steel 304 Flange

- Long Weld Neck Flanges

- Pipe Flanges

- Orifice Flange

- WNRF Flanges

- RTJ Flanges

- Puddle Flanges

- Orifice Plates

- Tube Sheet

- Socket Weld Flanges

- Plate Flanges

- Loose Flanges

- Lapped Joint Flanges

- Reducing Flanges

- BLRF Flanges

- Blind Flanges

- Spectacle Blind Flange

- Hydraulic Pipe Clamp

- Forged Pipe Fittings

- Stainless Steel Sheet

- Industrial Valves

- Tube Fittings

- Single Ferrule Hydraulic Fittings

- 37 Degree Flare Fittings

- Instrumentation Tube

- Adapter Fittings

- Ferrule Tube Fittings

- Double Ferrule Fittings

- Stainless Steel Tube Fittings

- Stainless Steel Hydraulic Fitting

- Precious Pipe Fitting

- Festo Push Fitting

- Din 2353 Hydraulic Tube Fittings

- Hydraulic Bite Type Fittings

- Hydraulic Ferrule Fittings

- Ermeto Tube Fittings

- O-Ring Face Fittings

- Marine Tube Fitting

- Nuts and Ferrule Fittings

- Bulkhead Tube Fitting

- Swagelok Fittings

- Pneumatic Fittings

- SS Adapter Fittings

- Female Connectors

- SS Cross Fittings

- Stainless Steel Camlock Coupling

- Hydraulic Quick Release Coupling

- Quick Release Couplings

- Marine Tube Fitting

- Ms Hydraulic Fittings

- Cs Hydraulic Fittings

- Weld Nipple Fittings

- Voss Equivalent Fittings

- Weld Adapter With Weld Nipple

- 400 Bar Hydraulic Tube Fittings

- 200 Bar Hydraulic Tube Fittings

- DK-LOK Equivalent Fittings

- Industrial Gaskets

- RUBBER GASKET

- Caf Gasket / Cnaf Gasket

- Spiral Wound Gaskets

- Pipe Flanges Gaskets

- API Gasket

- Octagonal Ring Gasket

- Soft Iron Ring Joint Gasket

- Spiral Wound Gasket

- Metal Gasket

- Oval Ring Joint Gasket

- Stainless Steel Ring Joint Gasket

- RTJ Gaskets

- Rubber O Ring

- Dowty Seal

- Graphite Gasket

- Ring Joint Gaskets

- Round Bar

- Alloy 20 Round Bar

- Cast Iron Round Bar

- EN Round Bar

- Inconel Round Bar

- Nitronic 50 Round Bar

- Stainless Steel Bright Bar

- Stainless Steel Round Bar

- Super Duplex Round Bar

- Super Duplex Steel Round Bar

- Tungsten Round Bar

- 17-4 PH Stainless Steel Round Bar

- Stainless Steel 304 Round Bar

- Stainless Steel 321 Round Bar

- Stainless Steel 304 Bright Bar

- Stainless Steel 304L Round Bar

- Stainless Steel 316 Round Bar

- 410 Stainless Steel Round Bar

- Stainless Steel Round Bars 904L

- Stainless Steel Rods

- 309 Stainless Steel Round Bar

- Alloy Round Bar

- Grey Cast Iron Round Bar

- Round Bars

- Aluminium Products

- Aluminium Tubes

- Aluminium Pipes

- Aluminum Coils

- Insulation Aluminum Coil

- IPS Aluminium Tubes / Aluminium IPS Pipe / Aluminium IPS Tubes

- Aluminium Industrial Pipes

- Aluminum sheets

- Aluminium Chequered Plates / Aluminum Checkered Sheet / Aluminum Checkered Plate

- Aluminium Round Bar

- Aluminium Bronze Rod

- Aluminium Angle

- Aluminum Alloy Sheets / Aluminum Sheets / Aluminium Sheets

- Aluminum Bronze Plate

- Aluminum Wires

- IPS Aluminium Tubes Aluminium IPS Pipe Aluminium IPS Tubes

- Compression Fittings

- Pneumatic Products

- Needle Valves

- Hose And Assemblies

- Plasma Cutting Machine

- Weld Stud

- Manifold Valves

- Duplex Steel Manifold Valves

- Hastelloy Manifold Valve

- SS Manifold Valves

- Stainless Steel 316 Manifold Valves

- 2 Way Manifold Valves

- Manifold Valves

- 3 Way Manifold Valves

- 5 Way Manifold Valve

- Block And Bleed Gauge Valves

- SAE 6162 Flanges

- Super Duplex Steel S32750 / S32760 Manifold Valves

- Incoloy 825 Manifold Valves

- Inconel 625 Manifold Valves

- Stainless Steel 304 Manifold Valves

- Inconel Manifold Valve

- Monel Manifold Valves

- Ss 316 Manifold Valve

- Ss 304 Manifold Valve

- Five Valve Manifold, Direct Mount T Type

- Five Valve Manifold Remote Mount

- Hastelloy C276 Manifold Valves

- Ptfe Manifold Valve

- Stainless Steel Manifold Valves

- Carbon Steel Manifold Valves

- Monel Sheet

- Copper Coils

- Hydraulic SAE Flanges

- Structural Steel Products

- Ball Valves

- Bronze Products

- Hastelloy Products

- Refractory Anchors

- Brass Products

- Pressure Gauges

- ERW Pipes

- Microwave Wave Guides

- Brass Tube Fittings

- Titanium Products

- Base Plate

- Condensate Pot

- Metal Pipes

- Polymer Rods

- Stainless Steel Tube Coil

- Expansion Bellow

- Nickel Alloy Products

- Flange Guards

- Dish End Cap

- Welding Consumables

- Stainless Steel Shims

- Cupro Nickel Rods

- Lead Balls

- Nickel Wire

- Half Pipe Sleeve

- Beryllium Copper Wire

- Boiler Steel Plates

- Eye Bolts

- Perforated Sheets

- Metal Powder

- Stainless Steel Sheets

- Stainless Steel 310 Sheets

- Stainless Steel Foil

- Stainless Steel 304 Sheet

- Stainless Steel 309 Sheet

- SS 904L Plate

- Stainless Steel Plate

- Stainless Steel Chequered Plates

- 304 Stainless Steel Plate

- 316 Stainless Steel Plate

- 316L Stainless Steel Plate

- Stainless Steel 321 Plate

- Stainless Steel 310 Plates

- SS 316 Coil

- SS 304 Coil

- Cold Rolled Steel Sheets 304 / 316 / 309 /904 / 310 / 410

- Industrial Thermowell

- Tantalum Products

- Molybdenum Products

- Niobium Products

- Aerospace Fasteners

- Pipe Fittings As Per Type

- Pipe Nipple

- Return Bends

- Lined Fitting ( PTFE Lined / PP Lined / HDPE Lined /Etc)

- Stainless Steel Tee

- Epoxy Coating Pipe Fitting

- Stainless Steel Investment Casting Pipe Fittings

- Buttweld Pipe Fittings

- Stainless steel Bushing

- Pipe Plugs

- Union Fitting

- Pipe Adapters

- Lateral Tee

- 3D Bend

- Hose Nipples

- Pipe Bend

- Pipe Elbow

- Stainless Steel Elbow

- Long Radius Bend

- Stainless Steel Couplings

- Heat Exchanger Tube Plug

- 5D Bend

- Hex Nipple

- Steel Rings

- Hose & Hose Assemblies

- Pipe Clamps

- Flanges as per Material Grade

- Flange as per Standard

- Industrial valves

- Butterfly Valves

- Industrial Valves

- Valve Key

- Knife Gate Valves

- Gate Valves

- Globe Valves

- NRV Valves

- Plug Valve

- Instrumentation Check Valves

- Flanged Valve

- Lined Valves

- Flanged Ball Valve

- High Pressure Ball Valve

- Hydraulic Ball Valve

- Investment Casting Ball Valve

- Ball Valves

- Stainless Steel Ball Valve

- SS Needle Valve

- SS OD Needle Valves

- High Pressure Needle Valves

- Double Ferrule Needle Valve

- Swagelok Needle Valves

- Parker Needle Valve

- Plasma products

- Gauge valves

- Copper Products

- Monel products

- Customized Products

- HYDRAULIC PIPE & HYDRAULIC TUBE

- Tungsten Products

- Inconel Products

- Lead Products

- Pipes

- Fittings As per types

- Flanges

- Tubes

- Fasteners

- Forged Fittings

- SS Product

- Stainless Steel Plate & Sheet

- Valves

- Stainless Steel 316 Instrumentation Ball Valves

- Double Compression Needle Valve

- Duplex Steel Instrumentation Ball Valves

- KHB Ball Valve

- PTFE Needle Valve

- 2 Way Hydraulic Ball Valve

- Three Piece Screwed End Ball Valve

- Hastelloy C276 Needle Valve

- Pp Flange Guard

- Hastelloy Needle Valve

- Monel Needle Valve

- Stainless Steel 304 Needle Valve

- Stainless Steel Needle Valve

- Stainless Steel 316 Needle Valve

- Inconel 625 Needle Valve

- Inconel Needle Valve

- Carbon Steel Needle Valve

- Duplex Steel Needle Valve

- SS310 Needle Valve

- OD X THRD Needle Valves

- Needle Valve Ss

- Swagelok parker Needle Valves

- Stainless Steel threaded Needle Valve

- Ss Needle Valve Screwed

- CS Needle Valve

- Stainless Steel 304 Instrumentation Ball Valves

- Inconel Instrumentation Ball Valves

- Monel Instrumentation Ball Valves

- Hastelloy Instrumentation Ball Valves

- Stainless Steel Instrumentation Ball Valves

- Pp Flanged Ball Valve

- SS Flanged Ball Valve

- CS Flanged Ball Valve

- PTFE Ball Valve

- Ss Three Piece Flanged End Ball Valve

- Three Piece Flanged End Ball Valve

- KHB 2 Way Ball Valve

- Hydraulic 2 Way Ball Valve

- Hydraulic High Pressure Ball Valves

- Flanges as per Standard

- Hydraulic Pipe Clamps

- Pipe Support Clamp

- Stainless Steel Round Bar

- Pneumatics

- CNC Cutting Machine

- Duplex & Super Duplex Products

- Industrial Products

- IS 1239 Black ERW Pipe and Tube

- Air Header, Condensation Pot & Syphon TUBE

- Stainless Steel Pipes & Tubes

- Quick Release Coupling

- Polymer

- Metal Coils

- Alloy Steel Products

- Copper Nickel Products

- Industrial Materials

- Round Bars

- Aerospace Products

- Wires

- Mild Steel Products

- Sheet Plates Coils

- Oil Field Equipment

- Thermowell

- Contact Us

Alloy 20 Pipe Fittings

100 INR/Number

Product Details:

- Flexibility Rigid

- Diameter DN15DN600

- Tensile Strength 551 MPa min

- Coating Type No external coating / as specified

- Bend Radius STD / Custom as required

- Connection Type Buttweld, Socket Weld, Threaded

- Yield Strength 241 MPa min

- Click to view more

X

Alloy 20 Pipe Fittings Price And Quantity

- 10 Number

- 99.00 - 500.00 INR/Number

- 100 INR/Number

- Rockwell B95 max

- Excellent resistance to sulfuric acid and chloride stress corrosion cracking

- 8.1 g/cm³

- Non-magnetic

- RoHS, PED 2014/68/EU, NACE MR0175

- Hot forming / Cold forming

- Smooth

- Wooden Boxes, Cartons, or as required

Alloy 20 Pipe Fittings Product Specifications

- Metal-to-Metal

- Pipe Fittings

- Pickled, Polished

- Silvery Metallic

- +/- 10% (can vary as per customer requirement)

- Class 150, Class 300, Class 600, Class 900

- SCH 10S, SCH 40S, SCH 80S, SCH 160, XXS or as required

- Alloy 20 (Carpenter 20 / UNS N08020)

- Round

- -46C to 425C

- NPT, BSP (for threaded fittings)

- 1/2 to 24 (DN15 to DN600)

- Petrochemical, Chemical Processing, Food Processing, Pharmaceutical, Marine, Power Generation

- Elbow, Tee, Reducer, Coupling, Cap, Stub End, Cross, Nipple, etc.

- Rigid

- 551 MPa min

- DN15DN600

- ASTM B366 / ASME SB366

- Welded, Seamless, Threaded

- Custom lengths as required

- No external coating / as specified

- Buttweld, Socket Weld, Threaded

- Corrosive and chemical environments

- STD / Custom as required

- 241 MPa min

- Alloy 20 / UNS N08020 / W.Nr. 2.4660

- Rockwell B95 max

- Excellent resistance to sulfuric acid and chloride stress corrosion cracking

- 8.1 g/cm³

- Non-magnetic

- RoHS, PED 2014/68/EU, NACE MR0175

- Hot forming / Cold forming

- Smooth

- Wooden Boxes, Cartons, or as required

Product Description

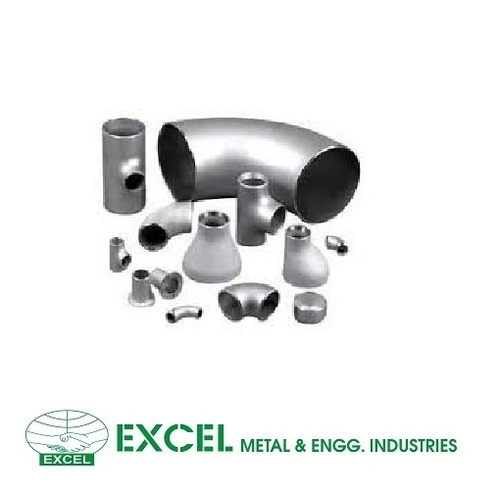

Alloy Steel Buttweld Fittings

Range : 1/2"NB TO 48"NB IN SCH: 20, 30, 40s, 80s, 10, 20, 40, STD, 60, 80, XS, 100, 120, 140, 160, XXS available with NACE MR 01-75

Type : SEAMLESS , WELDED, FABRICATED

Form

- Elbows in Long & Short Radius in 45 deg, 90 deg, 180 deg.

- Equal, Unequal Tee & Barred Tee.

- Eccentric Reducer & Concentric Reducer.

- Caps & Crosses.

- Long & Short Stub End.

- Swage Nipple & Barrel Nipple.

Alloy Steel Long Radius BendLong Radius Bend, Piggable Bend, Hot Bend with Radius R3D, 5D, 6D, 8D, 10D & 20D.

Minimum wall thinning rate and ovality No wrinkle

Form

Elbow 45 deg and 90 degree, Tee , Union, Full & Half coupling, Cross, Cap, Swage Nipple, Plug, Bush

Excellent Corrosion Resistance for Demanding Applications

Alloy 20 pipe fittings are specifically designed to perform in highly corrosive environments, making them ideal for applications dealing with sulfuric acid and chloride stress corrosion cracking. Their robust chemical composition enables long-term durability and performance, even under substantial operational stress. These qualities make Alloy 20 the preferred choice for industries that require both reliability and extended service life.

Versatile Shapes and Customizable Sizes

From elbows and tees to reducers and stubs, Alloy 20 pipe fittings come in a range of shapes (such as round) and can be fabricated in sizes from DN15 to DN600 with customizable thickness, bend radius, and length. Installation is adaptable, offering welded, seamless, or threaded connections-including NPT or BSP threading. This ensures compatibility with diverse piping systems and design requirements.

FAQ's of Alloy 20 Pipe Fittings:

Q: What makes Alloy 20 pipe fittings suitable for corrosive environments?

A: Alloy 20 pipe fittings offer excellent corrosion resistance, especially against sulfuric acid and environments prone to chloride-induced stress corrosion cracking. Their unique chemical composition ensures longevity and reliability in challenging conditions often found in petrochemical and chemical processing industries.Q: How are Alloy 20 pipe fittings manufactured and finished?

A: These fittings are produced using hot or cold forming techniques, followed by surface treatments like pickling or polishing for a smooth, silvery metallic finish. Each fitting can be finished to meet specific project needs and quality standards, ensuring optimal performance and durability.Q: What standards and certifications do Alloy 20 pipe fittings comply with?

A: Alloy 20 pipe fittings meet the requirements of ASTM B366 and ASME SB366, and conform to RoHS, PED 2014/68/EU, and NACE MR0175 standards. This ensures they are suitable and safe for global markets and critical applications.Q: Where are Alloy 20 pipe fittings commonly used?

A: Due to their superior corrosion resistance and mechanical properties, these fittings are widely used in petrochemical plants, chemical processing, food and beverage production, pharmaceuticals, marine environments, and power generation facilities.Q: What connection types are available for Alloy 20 pipe fittings?

A: You can choose from buttweld, socket weld, and threaded connections (compatible with NPT or BSP thread types) to suit various pipeline designs and installation preferences.Q: How is quality and dimensional accuracy ensured in Alloy 20 pipe fittings?

A: Each fitting is manufactured with a standard tolerance of +/-10% (customizable as per customer requirements) and undergoes stringent quality checks to guarantee compliance with material grades (UNS N08020/W.Nr. 2.4660) and international standards.Q: What are the packaging options for safe delivery of Alloy 20 pipe fittings?

A: To ensure safe handling and transportation, these fittings are securely packed in wooden boxes, cartons, or as specified by the customer, safeguarding the components until they reach your site.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email